Hi Hans, would you like to tell us more about ECCO?

ECCO is a family-owned company that was started in 1963 by the Danish Karl Toosby and was then called Venus. Toosby was then production manager at a shoe company in Copenhagen but had always aimed to start his own business. ECCO creates its shoes with a strong focus on the anatomy of the foot and is based on the watchword “pleasant walking”, an idea that first entered the company in the 70s. The shoes are created based on biomechanics, where the company has scanned and taken measurements of 2,500 feet. From this data, an anatomically correct last has then been created, as a basis that fits many feet to start from. A lot of time and effort is put into adapting the shoes that are produced to what feet actually look like.

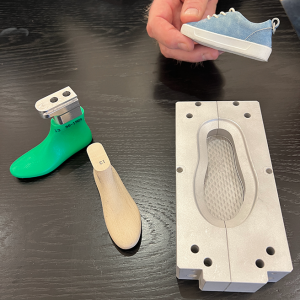

Unlike other players on the market, ECCO produces its shoes by casting a two-component sole on the last, so-called Fluidform, instead of gluing on a finished sole. This results in shoes that are light, flexible, and shock-absorbing. It also contributes to the shoes being snug and comfortable to walk in.

Photo: Hans shows miniatures of the process of molding the sole of a shoe.

ECCO’s focus is to deliver stylish, comfortable, and practical shoes at an attractive price for the consumer. Getting value for money is obviously somewhat subjective, but I believe in meeting or exceeding the customer’s expectations. This can be done for example, by training the staff in the stores. With their expertise, customers are happy to choose the same brand and specific store for their next purchase. We notice how there are more troubled times now and how the consumer chooses with greater care what to spend money on, which affects the intermediate purchase trade. Those who have built up genuine knowledge and have capital in the company will be fine – people will always need shoes.

What is ECCO’s greatest strength and you and what market do you target?

One of our greatest strengths is that we are privately owned and that we can decide for ourselves what we want to invest in. We, therefore, don’t have to live up to the last quarter’s figures and answer to investors. We are approximately 20,000 employees in the company, where 90% work in direct production and 10% work towards the market. We have production in Portugal, Slovakia, and Indonesia, among others. Another strength is that we ourselves own all our production units and factories, which allows us to direct and have control over the process. We usually say that in this way we can control the entire process “from cow to shoe”. The process begins with us buying rawhides directly from the slaughterhouse, which we tan ourselves, and then make shoes from or resell the hides. We are a world leader in manufacturing different types of leather and have a large business branch that focuses solely on that. By far the biggest customer on that side is Apple, which buys our skin for their cases and shells. Two other important clients are Louis Vuitton and Michael Kors.

Photo: Hans showing us ECCO-produced leather.

This year you have worked at ECCO for 25 years, big congratulations on the anniversary! What would you say is the biggest difference between when you started to now?

We are much more global now than we were when I started. We are now present all over the world and are represented in a total of 93 markets. We are the third largest brand in our category. A big difference is that it is a completely different technology development today and we can therefore produce incredibly much more advanced products than we had the opportunity to do before. The possibilities are therefore much, much greater. That gives us a big advantage over other brands that haven’t been able to keep up with technology development in the same way. We want to be at the forefront when it comes to technology and be able to continue producing advanced products.

Hans shows an example in the shoe Multivent, which has so-called “surround technology”, which means that the shoe has built-in ventilation through the sole. Via the holes from the inner sole and out through the outer sole, the air from the shoe can escape, while a GORE-TEX cover ensures that no water can enter the shoe. This regulates the heat in the shoe and provides a 1-1.5 degree cooler foot climate, which allows the feet to be in the comfort zone of around 28-32 degrees.

Photo: The Multivent shoe has ventilation through the sole.

What are your best tips for succeeding as a salesperson in the shoe industry?

My main tip is that you should know your products, but it is also important to have knowledge of finances as this ultimately means that you have a greater understanding of the customer’s finances. As a salesperson, you also need to learn the basics of sell-through rate, turnover rate, and gross profits and what affects them. You need to know all this in order to have an understanding of your customers, to be able to present a business proposal based on their finances, and to have a good dialogue with them.

When it comes to administrative errors, such as mis-delivery and such, my advice is to address them immediately and not drag them out. Be solution-oriented towards the customer and keep your promises, and the relationship will be that much better.

What does the shoe industry look like today and what does the development look like in the future?

The shoe industry has shrunk on a national level in the last five to ten years. There is tougher competition with fewer players and it is more difficult to make a profit today. At the same time, the industry has grown on a global level with e-commerce. However, I believe that there will always be room for competent and knowledgeable shoe retailers with capital and the desire to develop both themselves and their stores. I believe in those who are constantly working to stay current and give customers what they want. There will always be room for those who are passionate about satisfied consumers.

Visit ECCO’s digital showroom here.